Torsion

Torsion refers to the twisting of a specimen when it is loaded by couples (or moments) that produce rotation about the longitudinal axis. Applications include aircraft engines, car transmissions, and bicycles, etc.Units

Force X distance [lb-in or N-m]Notation and Convention

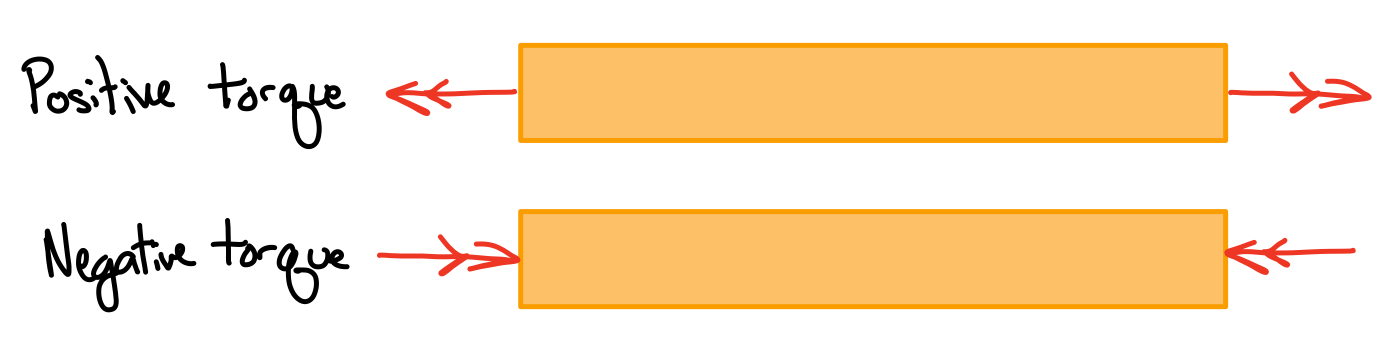

Sign convention

- \( \phi > 0 \) : counter clockwise

- \( \phi < 0 \) : clockwise

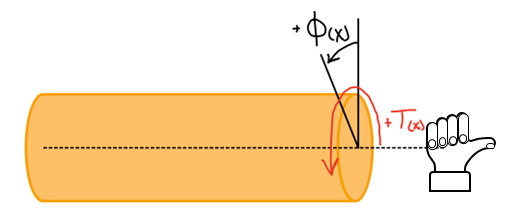

Right hand rule

Equilibrium

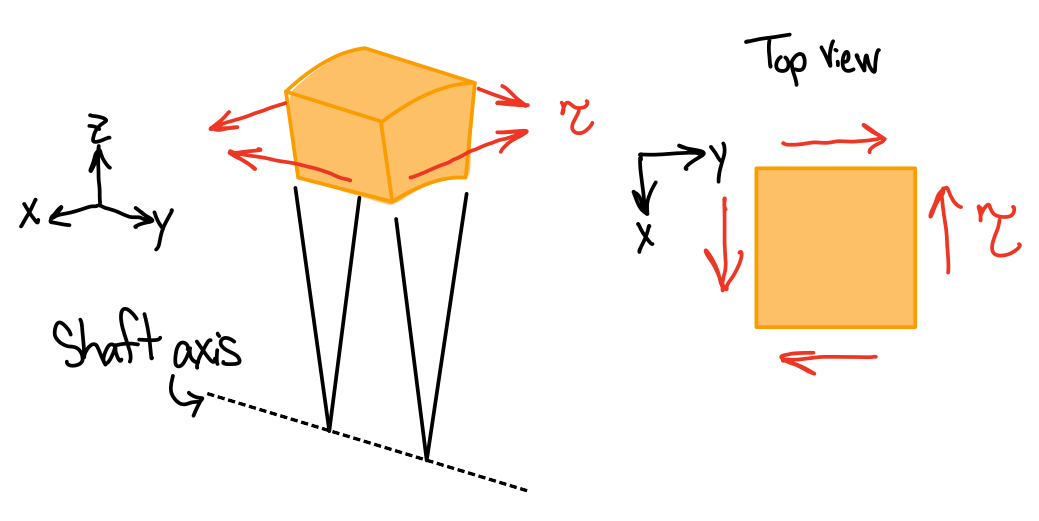

Single element shear stresses

- Statically indeterminate: must consider shaft deformations.

- Multi-planar: equilibrium requires the existence of shear stresses on the faces formed by the two planes containing the axis of the shaft

Assumptions

Torsion lines

- For circular shafts (hollow and solid): cross-sections remain plane and undistorted due to axisymmetric geometry

- For non-circular shafts: cross-sections are distorted when subject to torsion

- Linear and elastic deformation

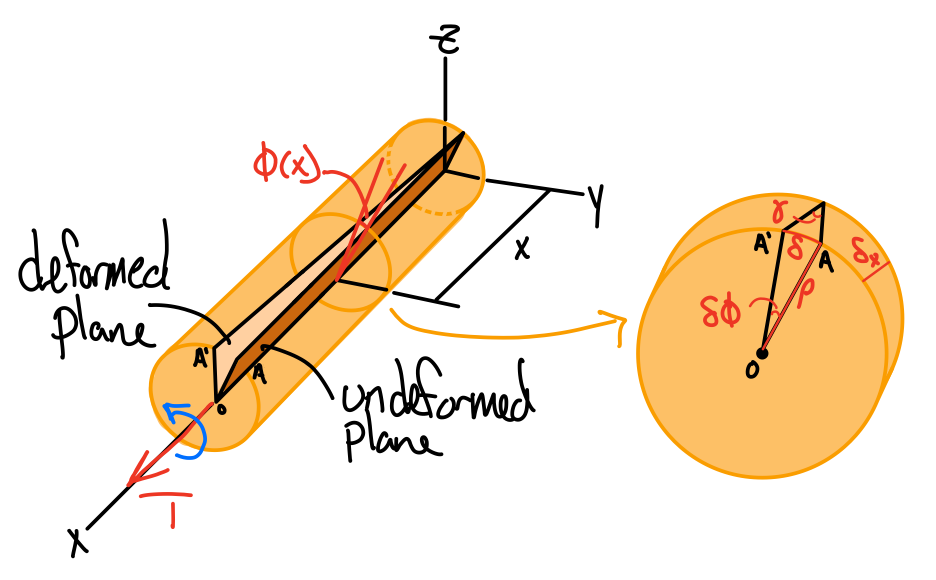

Shear Strain: Geometry of Deformation

Deformation

The twist rate is given by.

Moving terms.

Arc length.

- is proportional to the angle of twist

- varies linearly with the distance from the axis of the shaft

- is maximum at the surface

Shear Stress: Torsion Formula

Geometry

Hooke's law.

From equilibrium.

Elastic torsion formula.

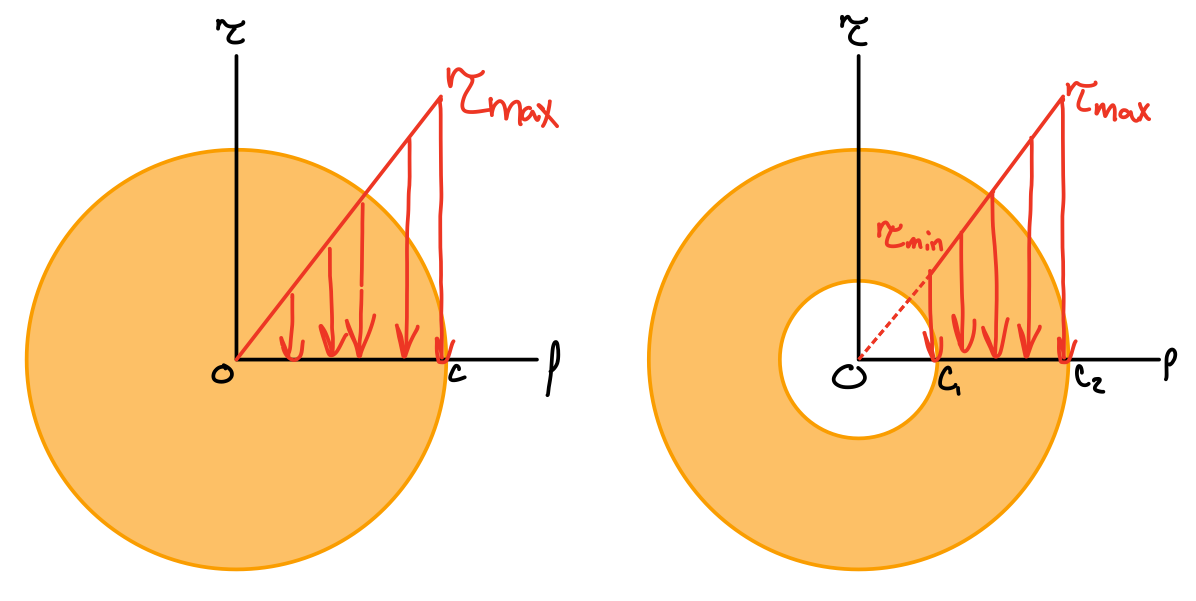

Stress distribution

Power.

Shear Stress: Polar Moment of Inertia

Solid shaft (radius and diameter). #tor-pmi

Hollow shaft (inner and outer radius). #tor-hol

Heads up!

For a moment of inertia summary, go to the "Moment of Inertia Summary" section of the Bending page.

Shear Stress: Angle of Twist

From observation:- The angle of twist of the shaft is proportional to the applied torque

- The angle of twist of the shaft is proportional to the length

- The angle of twist of the shaft decreases when the diameter of the shaft increases

Angle of twist.

Torsional stiffness.

Torsional flexibility.

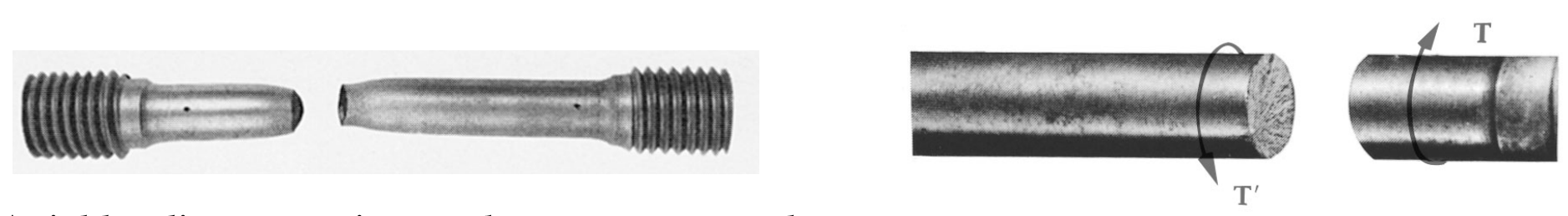

Types of Material Failure

Ductile materials generally fail in shear

Heads up - Extra!

Torsion of thin-walled hallow shafts builds on this content.

In general, the maximum shear stress is given by

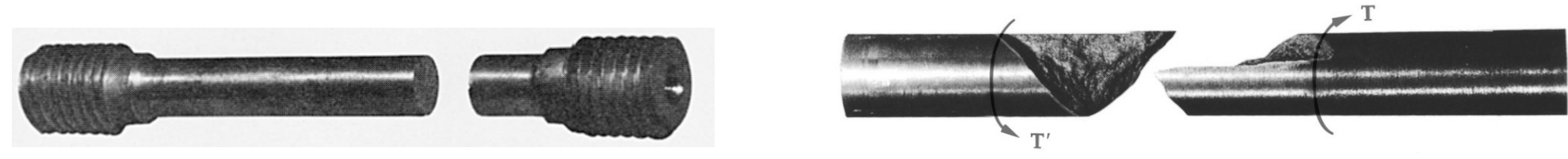

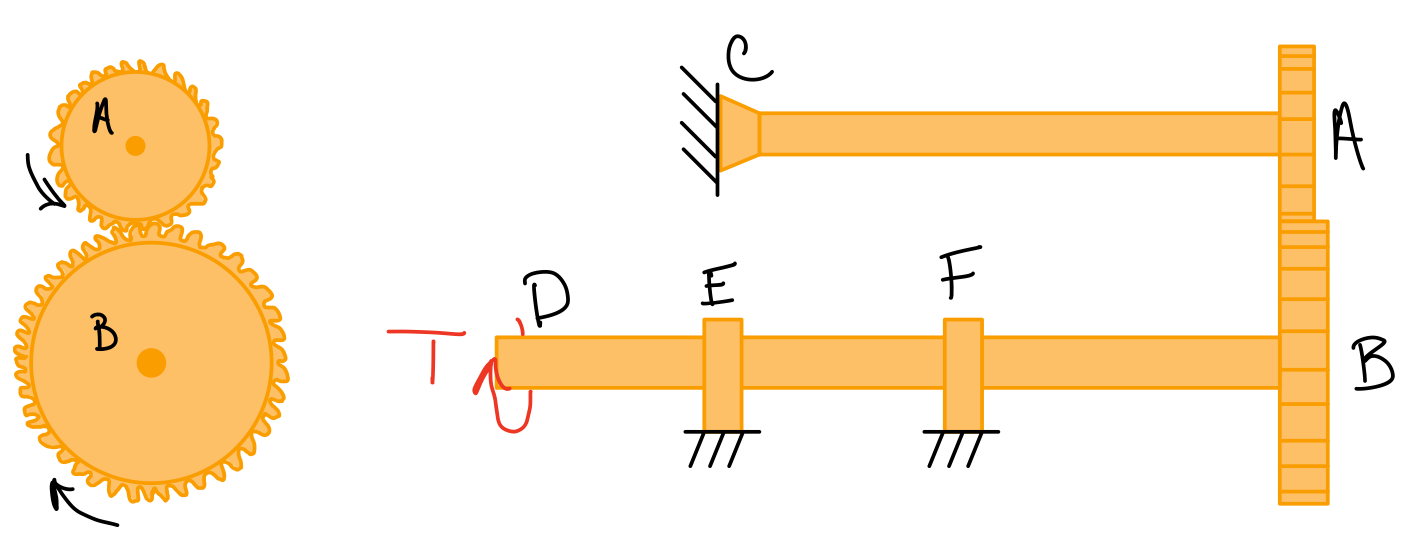

Gear Systems

Gear system

Common assuptions:

- Gears are perfectly rigid.

- The rotation axis is perfectly fixed in space.

- Gear teeth are evenly spaced and perfectly shaped so there is no gap to create lost motion.

- Gear tooth faces are perfectly smooth so there is no slip.

- Mated gears twist through the same arc length.

To solve:

- Draw a FBD for each shaft.

- Use the torsion equilibrium equations of each shaft to find the recation forces and torques.

- Use the shear stress equation to find the stresses in the shaft.

Gear ratio.

Angle of twist

Extra!

Power transmition can be used to find shear stress in gear shafts.

Maximum shear stress: