Introduction to Failure Theories

Failure theories are essential in predicting whether a material will fail under a given load. These theories help engineers design safe structures by considering different stress conditions. This document covers the most commonly used failure theories along with their mathematical formulations.

Maximum Normal Stress Theory

Principle: failure occurs when the maximum normal stress exceeds the material's ultimate tensile or compressive strength.

Failure Condition: \( \sigma_{1} > S_{ut} \quad \text{or} \quad \sigma_{3} < -S_{uc} \)

Where:

- \( S_{ut} \): Ultimate tensile strength

- \( S_{uc} \): Ultimate compressive strength

- \( \sigma_{1}, \sigma_{3} \): Maximum and minimum principal stresses

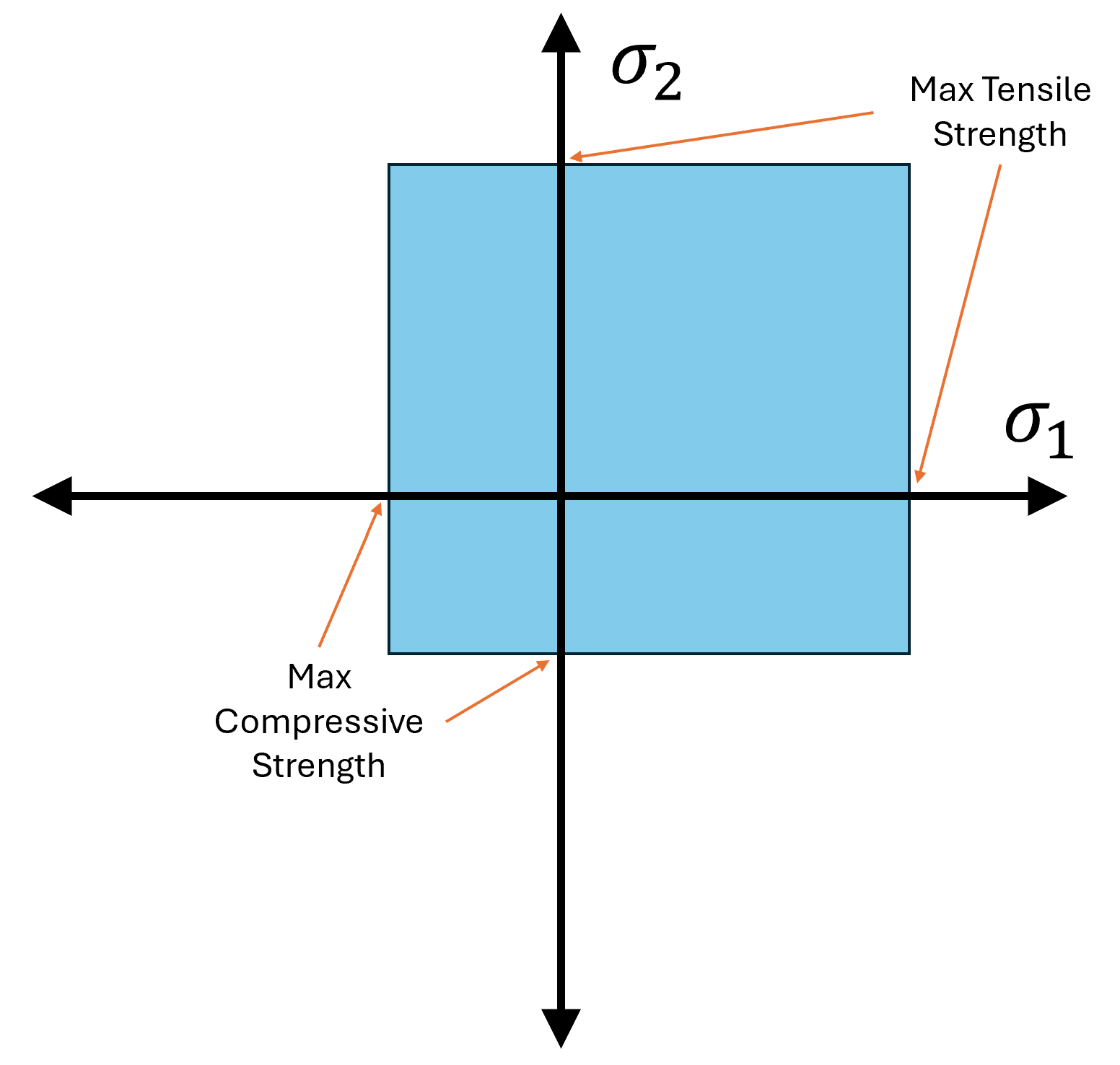

The image below is a plot of "safe" region according to maximum normal stress theory. By plotting the maximum and minimum principal stresses, the shaded region shows where the object will not fail. If a material is exposed to a stress that exceeds the tensile strength, that point would lie to the right, or above the shaded region. A stress that exceed the compressive strength would lie to the left or below the shaded region.

Applications

- Suitable for brittle materials like ceramics and cast iron.

- Not applicable for ductile materials due to plastic deformation.

Maximum Shear Stress Theory (Tresca Theory)

Principle: Failure occurs when the maximum shear stress exceeds the shear yield strength \( S_{sy} \).

Failure Condition: \( \tau_{\text{max}} = \frac{|\sigma_1 - \sigma_3|}{2} > S_{sy} \)

Since \( S_{sy} \) = \( \frac{S_{yt}}{2} \), we can write:

\( |\sigma_1 - \sigma_3| > S_{yt} \)

Where:

- \( S_{yt} \): Tensile yield strength

- \( S_{ys} \): Shear yield strength

- \( \sigma_{1}, \sigma_{3} \): Maximum and minimum principal stresses

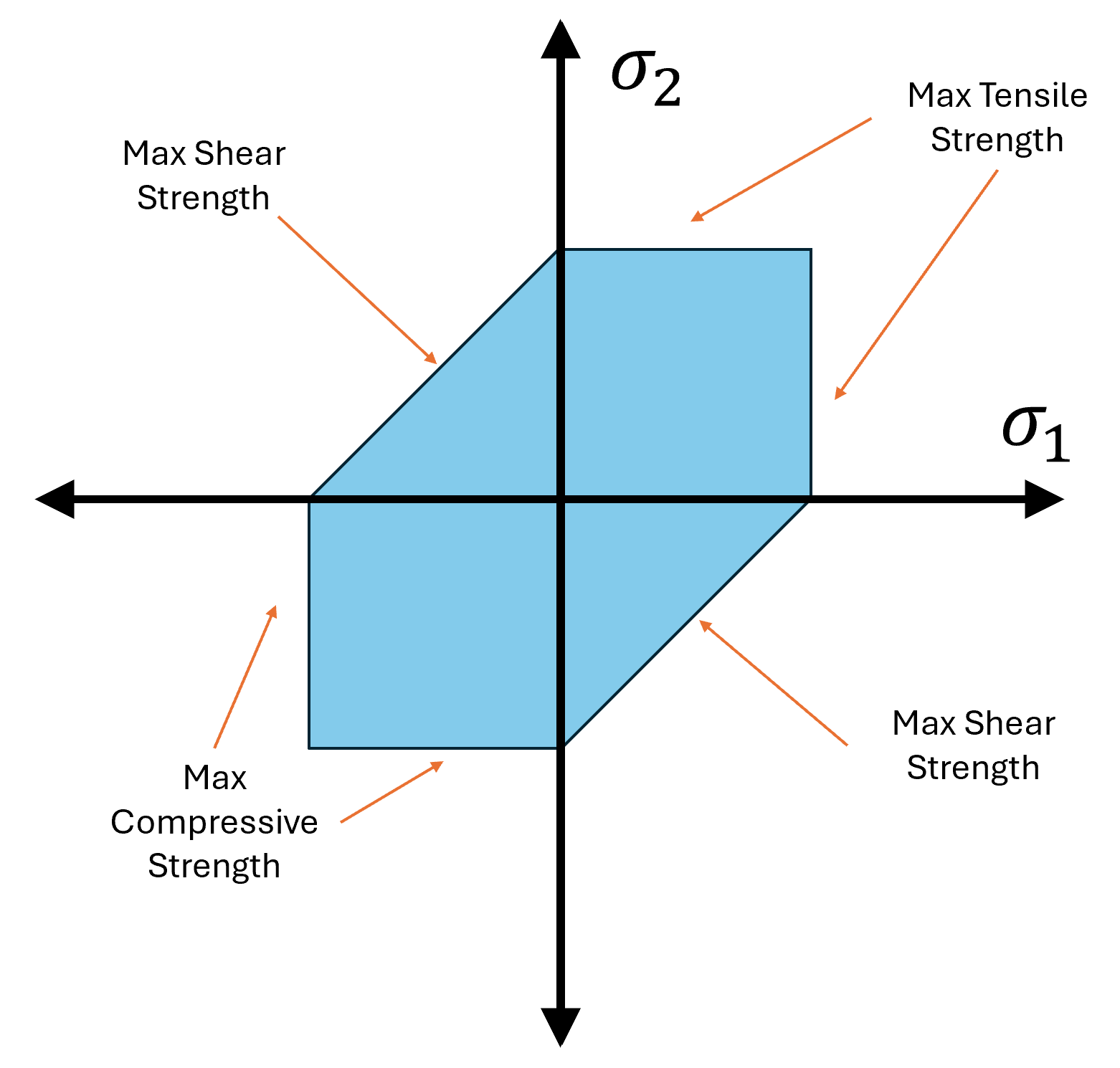

The image below is a plot of "safe" region according to maximum shear stress theory. By plotting the maximum and minimum principal stresses, the shaded region shows where the object will not fail. Since shear stress is proportional to the difference in the maximum and minimum principal stresses, we modify the safe region from the maximum normal stress theory to limit the maximum difference between the maximum and minimum principal stresses.

Applications

- Best suited for ductile materials like steel and aluminum.

- Used in mechanical and structural engineering design.

Maximum Distortion Energy Theory (Von Mises Theory)

Principle: Yielding occurs when the distortion energy per unit volume reaches a critical value.

Failure Condition: \( \sigma_{VM} = \sqrt{\frac{(\sigma_x - \sigma_y)^2 + (\sigma_y - \sigma_z)^2 + (\sigma_x - \sigma_z)^2 + 6(\tau_xy^2 + \tau_yz^2 + \tau_xz^2)}{2}} \)

or \( \sigma_{VM} = \sqrt{\frac{(\sigma_1 - \sigma_2)^2 + (\sigma_2 - \sigma_3)^2 + (\sigma_3 - \sigma_1)^2}{2}} \)

Failure occurs if: \( \sigma_{VM} > S_{yt} \)

For a 2D stress state \( \sigma_3 = 0 \)

\( \sigma_{VM} = \sqrt{\sigma_1^2 - \sigma_1\sigma_2 + \sigma_2^2}=\sqrt{ \sigma_x^2 - \sigma_x\sigma_y + \sigma_y^2 + 3\tau_{xy}^2} \)

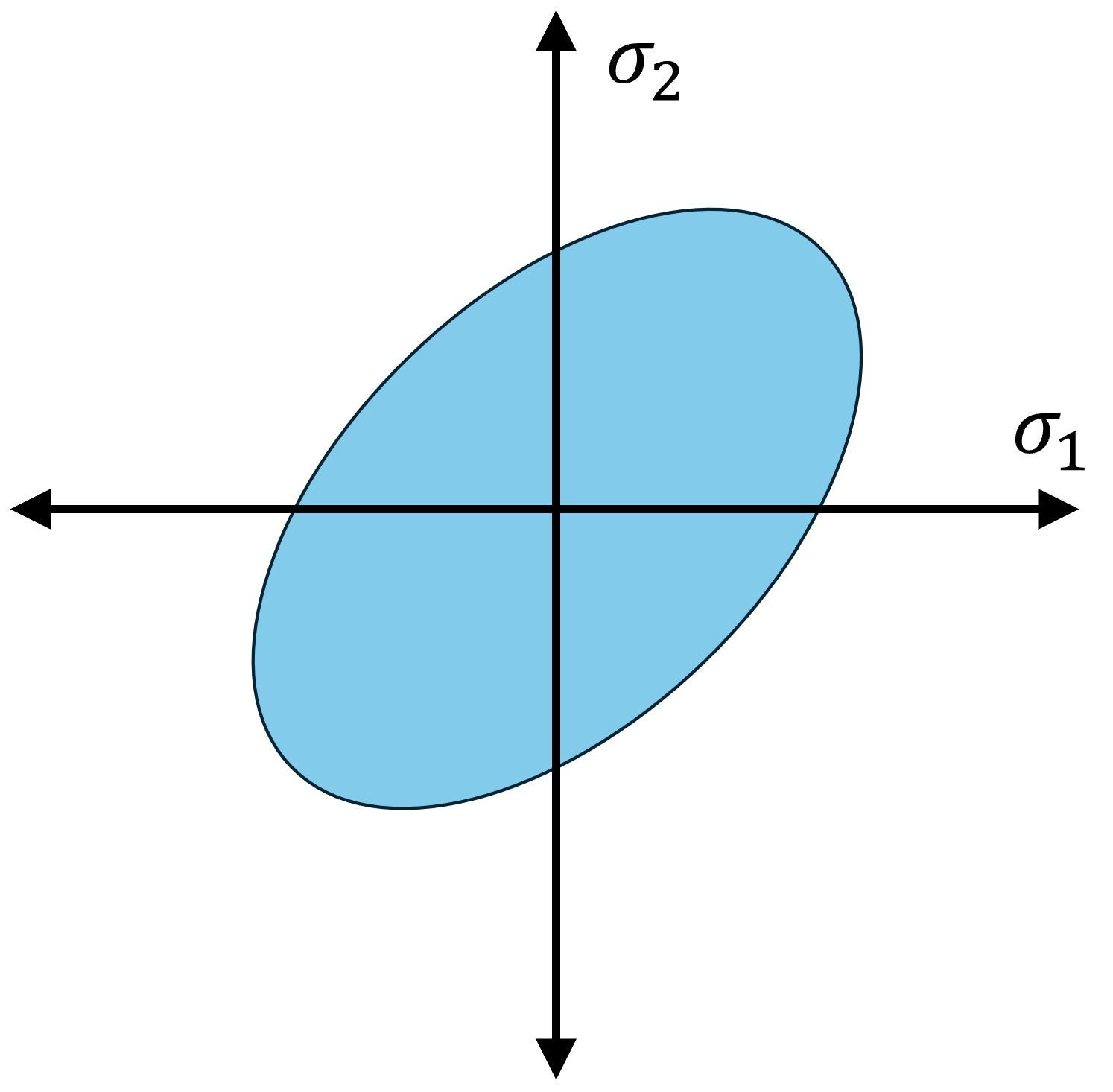

The image below is a plot of "safe" region according to maximum distortion energy theory. By plotting the maximum and minimum principal stresses, the shaded region shows where the object will not fail. For a 2D object, this region will appear as a rotated ellipse.

Applications

- Preferred for ductile materials.

- Used in finite element analysis (FEA) and plasticity theory.

Fracture Mechanics and Crack Propagation

Principle: Materials can fail when a crack propagates through them.

Failure Condition: \( K \geq K_c \)

Failure due to brittle fracture occurs when the Stress Intensity Factor \( K \) exceeds a material's Fracture Toughness \( K_c \)

We can compute the stress intensity factor according to

\( K = Y \sigma \sqrt{\pi a} \)

Where:

- \( K \): Stress intensity factor

- \( Y \): Geometric factor

- \( \sigma \): Applied stress

- \( a \): Crack length

Let us now walk through how to determine the value of each of these terms. \( \sigma \) will depend on the specific loading condition that is applied to the material. \( a \) is a geometric parameter that should be directly measured. \( K \) can be directly computed from \( \sigma \) and \( a \). This leaves \( Y \), the geometry factor. Identification of this value will usually be done with the use of lookup tables that contain the values of \( Y \) for a wide variety of geometries and loading conditions.

It is also valuable to recall that \( K_c \) is a material property that will often be listed along with other material properties.

Applications

- Used in failure predictions for materials with cracks.

- Important in aerospace, nuclear, and structural applications.

Conclusion

Each failure theory provides unique insights into material behavior. While von Mises theory is best for ductile materials, brittle materials require normal stress theory or fracture mechanics. Altogether, it is the responsibility of an engineer to identify the most appropriate theory and apply it to determine if a component will work as intended.