Axial Loading

Notation and Convention

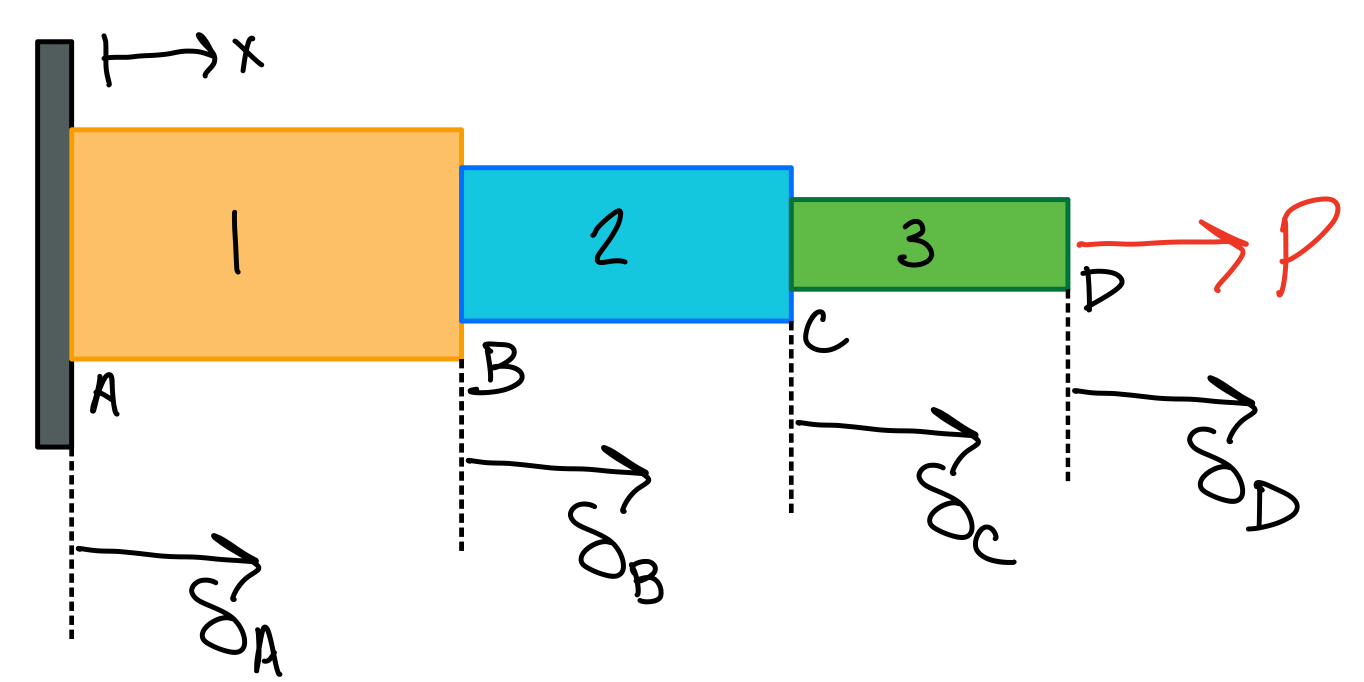

- Displacement of points in space: the movement of a point relative to its initial position in space (ex; \( \delta_B \) )

- Change in length of a segment: the relative displacement of a point with respect to another point (ex; \( \delta_{B/A} = \delta_B - \delta_A = \delta_1 \) ). This can be written multiple ways:

Notation.

- \( F>0 \) : tension

- \( F<0 \) : compression

- \( \delta>0 \) : elongation

- \( \delta<0 \) : contraction

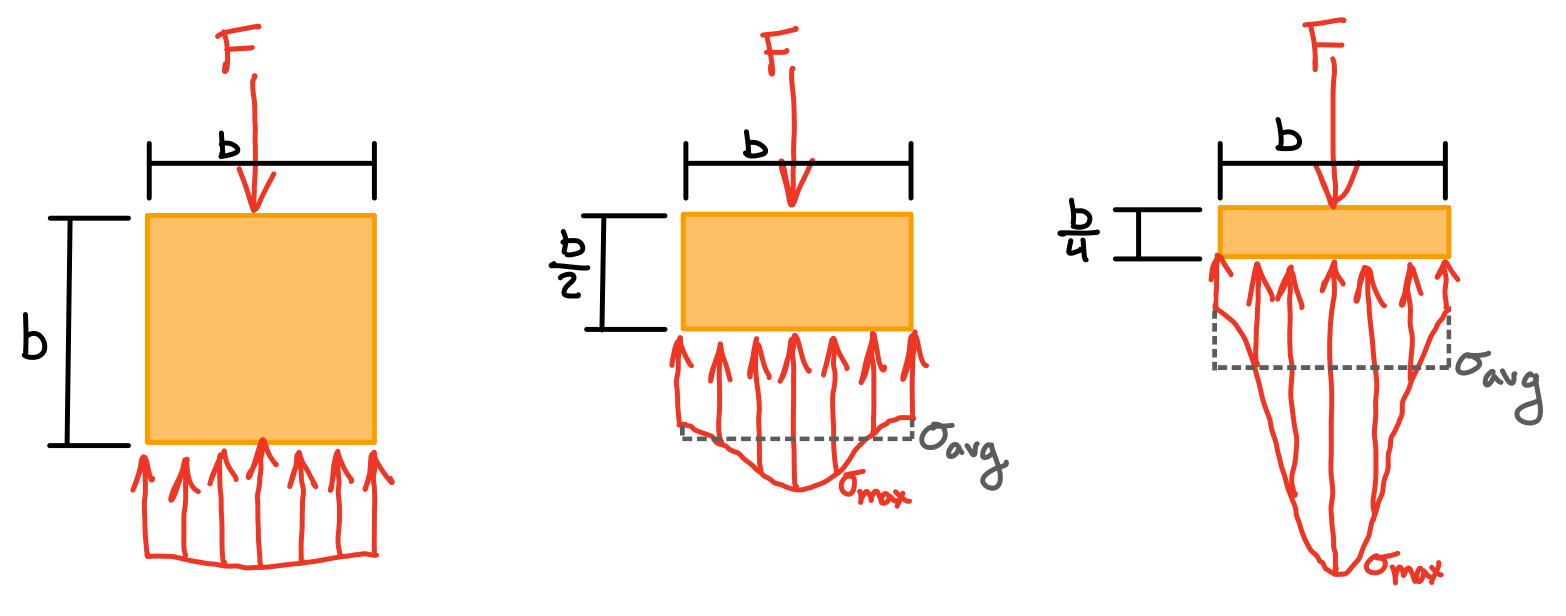

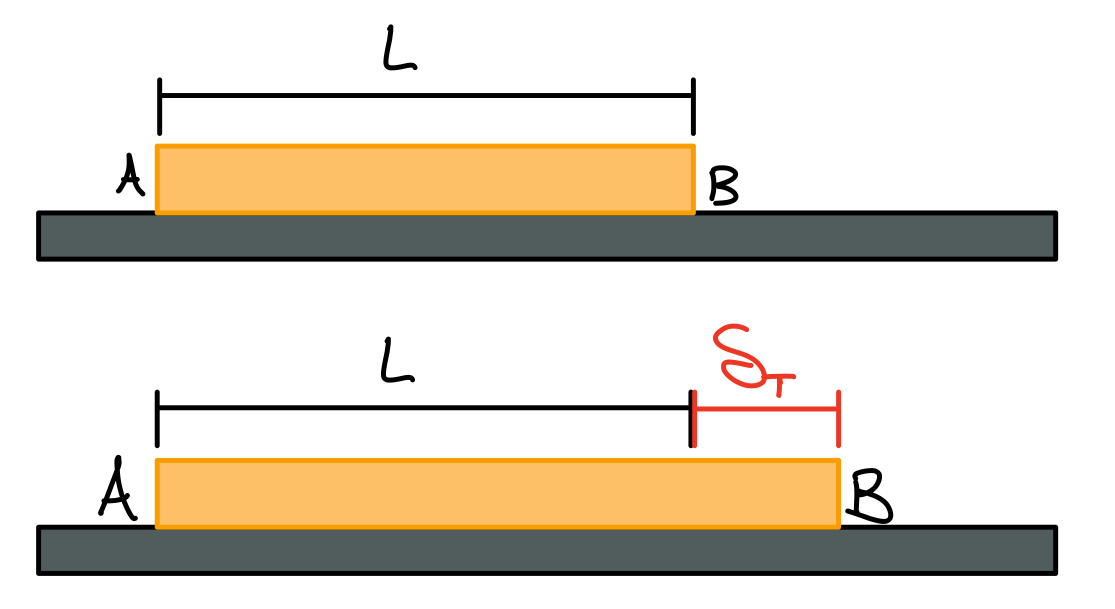

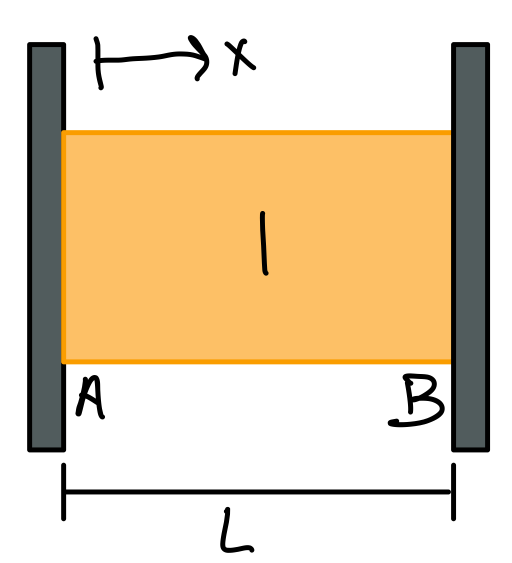

Saint-Venant's Principle: slender beam case

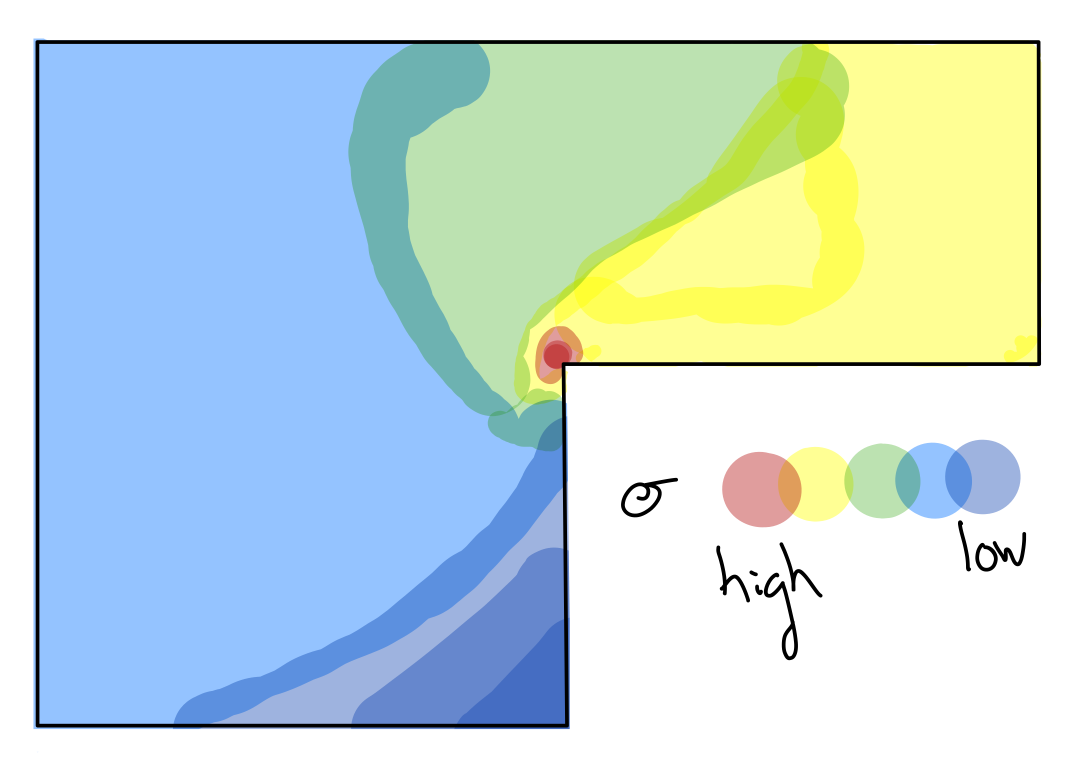

Stress analysis very near to the point of application of load \( P \). Saint-Venant's principle: the stress and strain produced at points in a body sufficiently removed* from the region of external load application will be the same as the stress and strain produced by any other applied external loading that has the same statically equivalent resultant and is applied to the body within the same region.

*farther than the widest dimension of the cross sectionAxially Varying Properties

For non-uniform load, material property and cross-section area:Principle of Superposition

Superposition: If the displacements are (1) small and (2) linearly related to the force components acting, the displacements caused by the components can be added up:General Solving Procedure

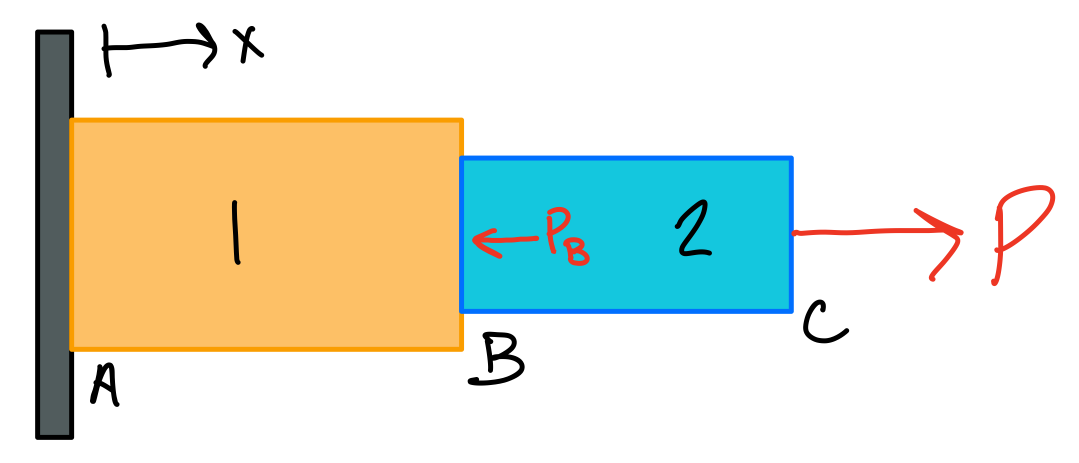

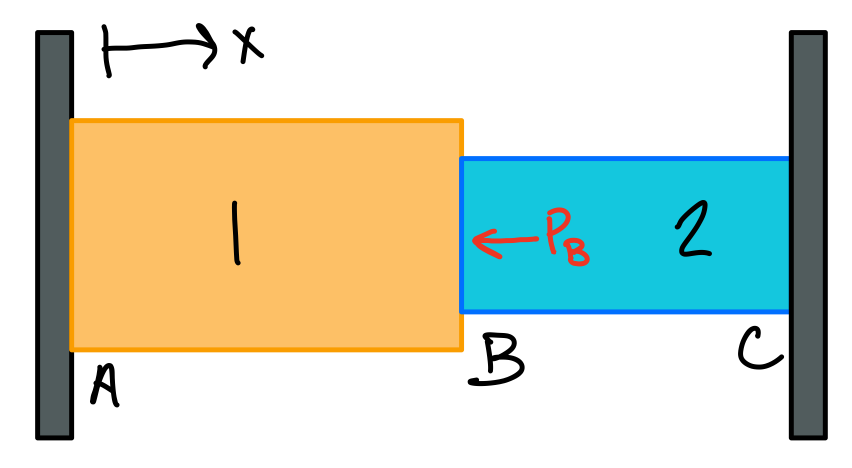

- Draw a FBD

- Equilibrium equations: force balance and moment balance

- Constitutive equations: stress-strain or force-displacement relations

- Compatibility equations: geometric constraints

Statically Determinate Problems

Statically Indeterminate Problems

Thermal Effects: Temperature Changes

Notation- \( \Delta T > 0, \sigma < 0 \) : Compression

- \( \Delta T < 0, \sigma > 0 \) : Tension

\( \delta_T \) , \( \varepsilon_T \) present in addition to elastic \( \delta_E \) , \( \varepsilon_E \) (from internal forces). Superposition (small strains):

Misfit Problems

A misfit problem is one in which there is difference between a design distance and the manufactured length of a material. Some misfits are created intentionally to pre-strain a member. (e.g. spokes in a bicycle wheel or strings in a tennis racket). This type of problem neither modifies the equilibrium equations (1) nor the force-extension relations, (2) but the compatibility equations, (3) need to be modified.Heads up!

Stress concentration factors build on this content in engineering materials and mechanical design.

The stress concentration factor is the highest at lowest cross-sectional area.

- Found experimentally

- Solely based on geometry